Mararka qaarkood marka aan iibsaneyno mishiinada iyo qalabka, waxaan rabnaa in aan ogaano in ay tayadoodu wanaagsan tahay oo aan lahayn cillado.Markaa dhinacyo badan ayaynu ka arki karnaa inay si toos ah u shaqaynaysomashiinka calaamadaynta waa cilladaan inta lagu jiro isticmaalka.Dhab ahaantii, sidoo kale waa mid aad u Fudud, inta badan marka laga eego dhinaca heerka socodka, sida loo eego si gaar ah, aan hoos ku falanqeyno;

1. Ka qiimaynta xasiloonida calaamadda: hagaaji si toos ahmashiinka calaamadaynta Xawaaraha sare ee loo dejiyay, xisaabi booska isha korantada ee calaamadda, ka dibna u kicin calaamadaynta isha korantada si degdeg ah oo joogto ah, xusuusnow inaad u fiirsato in calaamaddu si toos ah u socoto, oo jooji Ka dib kicinta, u fiirso booska korontadu isha ku hay calaamadda oo tiri tirada calaamadaha.Wanaagsanmashiinka calaamadaynta weligood ma soo saari doonaan calaamado ka badan tirada kiciyeyaasha.Dabcan, haddii aad mar kale kiciso calaamadaynta ka hor intaan calaamaddu dhammaan, Waxaa jiri kara calaamado yar.

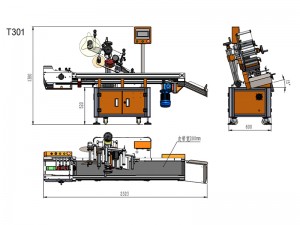

2. Fiiri: muuqaalka muuqaalka tooska ahmashiinka calaamadaynta waxay ka tarjumaysaa fikradda naqshadeeyaha ee mashiinka.Muuqaalka muuqaalkamashiinka calaamadaynta inta badan waxaan dhahnaa kaliya maaha inay tixraacdo bilicda, laakiin sidoo kale waxaa ku jira caqli-galnimada naqshadeynta qalabka, sida dhibka beddelka calaamadaha.Way fududahay in la hagaajiyo booska iyada oo aan la isticmaalin qalab, haddii interface man-mashiinku ay fududahay in la fahmo oo la shaqeeyo, iwm. Sidaa darteed, haddii amashiinka calaamadaynta waxa kaliya oo loogu talagalay in lagu dhamaystiro hawsha baakadaha, ama tixgelinta dhinaca bini'aadamka, waxaad ogaan doontaa adigoo eegaya muuqaalka.

3. Dhageyso: Sifooyinka otomaatiga ahmashiinka calaamadaynta go'aanso in matoorka calaamaduhu u baahan yahay inuu bilaabo oo uu si joogto ah u joojiyo.Haddii bilawga iyo joojinta dhawaaqa matoorka qalabka la ogaado in uu degdeg yahay inta lagu jiro isticmaalka, ka dibna si toos ahmashiinka calaamadaynta uu leeyahay nidaamyo aan ku filnayn ama dhibaato xulashada mootada.Inta lagu guda jiro habka rakibo eemashiinka calaamadaynta, haddii qaybaha aan si sax ah loogu rakibin qaybtan, ama ay jirto leexasho gaar ah, markaa dhibaatooyin kala duwan ayaa sababi doona inta lagu jiro hawlgalkasi toos ahmashiinka calaamadaynta.

Horudhac ku saabsan go'aaminta haddii mishiinku cilladaysan yahay gobolka ordaya waa halkan.Faahfaahinta, fadlan kala tasho goobtan: https://www.ublpacking.com/

Waqtiga boostada: Jan-17-2022