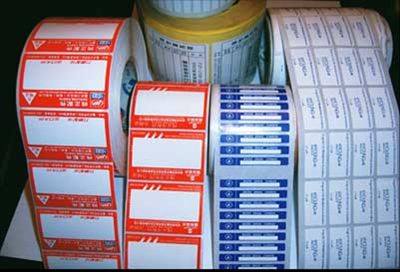

"Saddex"mashiinka calaamadayntaSummada Samaynta

1. Qalabka dusha sare.Adkaynta calaamaddu waa furaha tartanka.Sidaa darteed, walxaha dusha sare ayaa looga baahan yahay inay yeeshaan xoogaa xoog iyo qallafsanaan,

Qalafsanaanta calaamaddu waxay la xiriirtaa dhumucda walxaha iyo aagga;calaamadda, markaa markaad isticmaalayso walxo filim jilicsan,

Si loo kordhiyo dhumucdeeda ku habboon, waxaa guud ahaan la xakameeyey in ka badan 100um.Alaabta xaashida khafiifka ah, sida 60~70g/m2 warqad,

Mashiinka calaamadaynta dhalada wareegsanguud ahaan kuma habboona samaynta summadaha waaweyn, waxayna ku habboon tahay in lagu dhejiyo calaamado yaryar, sida summada qiimaha inta badan laga isticmaalo dukaamada waaweyn.

Qallafsanaanta xun ee calaamaddu waxay sababi doontaa in calaamaddu aysan soo bixin marka la calaamadinayo, ama calaamadda iyo warqadda hoose ayaa dib loo soo celin doonaa, taas oo keeni doonta calaamadaynta tooska ah inay guuldareysato.

2. Xoog sii daynta.Sidoo kale loo yaqaan xoogga diirinta, waa xoogga marka calaamadda laga sooco warqadda dhabarka.Xoog ku sii daaya iyo nooca xabagta, dhumucda iyo warqada dhabarka

Dahaarka silikon ee dusha sare wuxuu la xiriiraa heerkulka deegaanka marka la calaamadinayo.Awoodda sii dayntu aad bay u yar tahay,

Calaamaddu way fududahay in laga sooco warqadda hoose inta lagu jiro habka gudbinta, taasoo keenaysa hoos u dhaca summada;iyo xoogga sii dayntu waa mid aad u weyn, wayna adagtahay in calaamaduhu ka soocaan warqadda hoose.

Aan awoodin inuu soo bandhigoSidaa darteed, tilmaameyaal farsamo oo kala duwan waa in si buuxda loo xakameeyaa si loo ilaaliyo awoodda sii daynta ilaa xad macquul ah.

3. Warqadda hoose.Sidoo kale waa tilmaame muhiim u ah xakamaynta calaamadaynta tooska ah.Waxay u baahan tahay warqad hoose:

a.Daahan silikoon lebbisan oo dusha sare ah iyo xoog sii dayn joogto ah;

b.Dhumucdiisu waa labbis oo waxay leedahay xoogaa xajin ah si loo hubiyo inaysan jabin marka la calaamadinayo;

c.Waxay leedahay gudbinta iftiinka wanaagsan si loo hubiyo in shidmahu uu si sax ah u garto booska calaamadda

4. Tayada habaynta: jeexjeexa ka dib, labada dhinac ee warqadda hoose ayaa looga baahan yahay inay noqdaan kuwo siman oo bilaash ah si looga fogaado in warqadda hoose ay jabto marka xiisaddu isbedesho.

Iska ilaali inaad gooyso warqadda hoose ama aad dhaawacdo lakabka silikoon-dahaarka ah inta lagu jiro isgoysyada.Waxyeellada warqadda hoose iyo lakabka silikoon-dahaarka ah waxay u badan tahay inay dhacaan.

Waraaqda dhabarku way jabtay ama xabagta ku taal calaamaddu waxay soo dhex gashaa warqadda dhabarka, warqadda dhabarku lama daabicin oo warqaddii dhabarku waa jeexjeexday.

5. Intaa waxaa dheer, korontada taagan ee ku jirta calaamadda duubista waa in meesha laga saaraa ka hor inta aan la calaamadin calaamadinta mashiinka, sababtoo ah korontadu waxay sababtaa in calaamadda aan la soo bandhigin ama aan sax ahayn marka la calaamadinayo.

Waqtiga boostada: Nov-16-2021