Tobannaan sano oo horumar iyo horumar joogto ah ka dib,mashiinka calaamadaynta tooska ahwaxa uu gaadhay horumar horumarineed oo soo jiitay indhaha caalamka.Maalmahan, asal ahaan dhammaan shirkadaha wax soo saarka waxay isticmaali doonaan mashiinnada calaamadaynta si ay u fuliyaan baakadaha alaabta.Mashiinnada calaamadaynta waxay muddo dheer noqdeen mid ka mid ah mashiinnada aasaasiga ah iyo qalabka lagama maarmaanka u ah suuqa ganacsiga badeecadaha.Horumarka mustaqbalka, dadku waa inay si taxaddar leh u ballaariyaan suuqa iibka ee mashiinnada calaamadaynta tignoolajiyada tooska ah, si taxaddar leh u raadiyaan isbeddellada horumarka iyo fursadaha ganacsiga, oo ay doortaan heerarka isbeddelka horumarka ee ku habboon xeerarka warshadaha wax soo saarka si ay si taxaddar leh u ballaariyaan horumarka mustaqbalka ee warshadaha wax soo saarka.Meel gudaha ah.Habkan oo kaliya ayaa lagu heli karaa faa'iidooyinka dhaqaale ee weyn ee mashiinka calaamadaynta, taas oo u keeni doonta ku habboonaanta tiro badan oo shirkado wax soo saar ah.

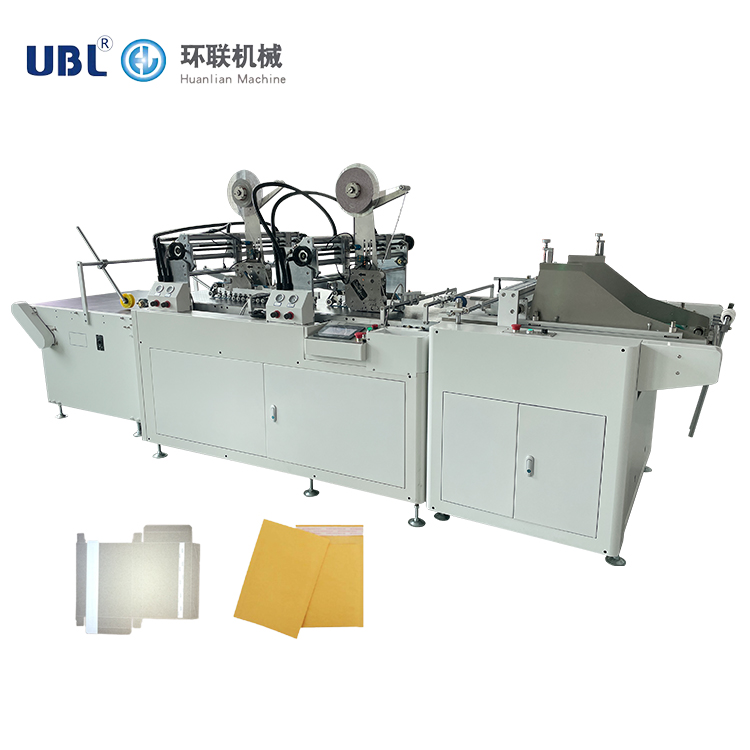

Mashiin calaamadaynta dhalada wareeg ah oo toos ah oo lagu taliyay moodel sax ah oo sare

Maanta, waxaan si faahfaahsan u soo bandhigi doonaa lixda dhibaato ee caadiga ah ee isticmaalka mashiinada calaamadaynta tooska ah:

1. Haddii saddexda faasas ee X, Y, iyo Z si magnetic ahaan loo kiciyo oo ay weheliyaan barta ugu dambaysa, si firfircoon looguma celin karo eber.

2. Marka la beddelo xuduudaha ugu muhiimsan ee jihaynta dhammaan faashashka, awoodda waa in la dami oo dib loo bilaabo.

3. Ka hor inta aanad bilaabin mashiinka calaamadaynta, dib u dhig booska mashiinka calaamadaynta eber ka hor inta aan la hawlgelin.

4. Haddii raadinta tixraaca firfircoon aan la dhammaystiri karin, marka hore gacanta ku xir dhidibka Z ee mashiinka calaamadaynta barta ugu dambeysa, ka dibna hoos u dhig dhidibka Y, ka dibna si firfircoon u raadi booska.

5. Si aad uga baxdo caaryada, booska hoose ee calaamadda waa in loo adeegsadaa booska badbaadada.Kaliya mashiinka calaamadaynta ayaa ku soo laaban doona booska mustaqbalka ee calaamadda si uu u guuleysto ama u lumiyo caaryada.

6. Marka alaarmiga servo motor uu la kulmo, oo xuduudaha ugu muhiimsan si firfircoon loo raadiyo ama buug-gacmeedka lama dhaqaajin karo, awoodda waa la dami karaa oo dib ayaa loo bilaabi karaa si loo tijaabiyo mar kale.

TransUnion Automation 14 Sano Soo Saaraha Xoogga

Ka dib markii aan soo bandhigo dhibaatooyinka caadiga ah ee isticmaalka mashiinka calaamadaynta tooska ah si faahfaahsan, waxaan u soo bandhigi doonaa habka dayactirka mashiinka calaamadaynta tooska ah qof walba si faahfaahsan.Marxaladani waa mudnaanta koowaad ee wax soo saarka dhabta ah ee Kooxda TransUnion.Ka dib 10 saacadood oo shaqo ah, qalabka mashiinka calaamadaynta waa in la xidhaa 30 daqiiqo waana in la qaado tallaabooyinka dayactirka ka hor inta aan dib loo hawlgelin:

1. Ka dib marka qalabka la shaqeeyo maalin kasta, inta badan korontada waa la gooyaa, waxaana la tirtiraa dusha sare ee qalabka, kursiga shaqada iyo boosaska kale.

2. Mashiinada iyo qalabka ayaa looga baahan yahay si loo hubiyo in tamarta shaqada ee qalabka korontada ee wareejinta ee xarumaha taageeraya codsiga, ka dibna dhammaan lacagaha caadiga ah ayaa la gelin karaa wax soo saarka.

3. Hubi qaybaha hawlgalka sida silsiladda gudbinta, oo isla markiiba nadiifi haddii ay jiraan wax cillado ah.Oo si sax ah u buuxi saliidda siman, oogada iliga ee qalabka gudbinta kasta si sax ah ugu dar dhibic saliid baabuur ah ama subag aan cusbayn si ay u siman yihiin.

4. Si joogto ah u hubi heerka adkaynta dhammaan isku xidhka xidhmooyinka barroosinka, oo isla markiiba adkee haddii la ogaado inay dabacsan yihiin.

5. Waa in aan la barakicin meelaynta saxda ah iyo qalabka lagu ogaanayo.Haddii loo baahdo, ka bilow bilowga.

6. Hubi in suunka gudbinta uu leexsan yahay iyo in kale.

7. Hubi in sahayda hawadu iyo xidhiidhiyayaasha ay dabacsan yihiin ama la soo riday.

Horudhac ku saabsan mashiinka calaamadaynta ee u baahan daryeel waa halkan.Faahfaahinta, fadlan kala tasho boggan:https://www.ublpacking.com/

Waqtiga boostada: Jul-22-2022